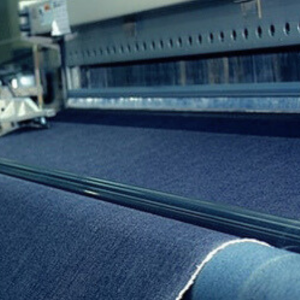

Denim Series

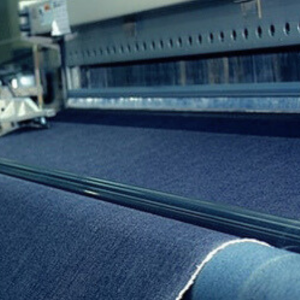

Our Denim manufacturing unit is dedicated to excellence. From using high-quality yarn to a skilled team handling R&D, dyeing, weaving, finishing, and inspection, all within the same production facility, we ensure top-notch denim fabric quality. Our commitment is to deliver the best denim fabrics for your needs.

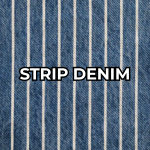

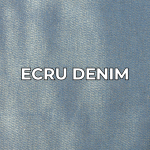

FABRIC RANGE :

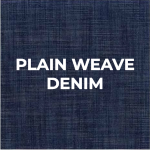

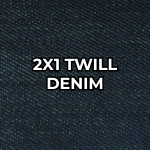

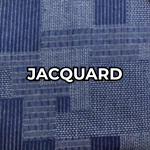

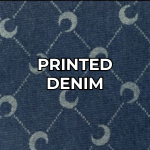

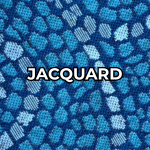

Denim Types : Plan & Twill Weave, Jacquard, Brocade etc.

Weight Range : 5 oz to 14.5 oz

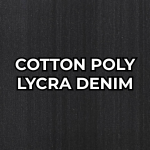

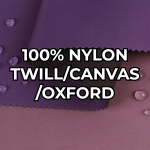

Yarn Types : OE, Ring Spun, Dual Core, 10D to 1200D Nylon and Polyester, etc.

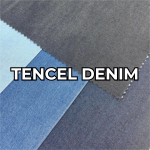

Sustainable Options : US Cotton, Recycled Cotton/Polyester, Modal, Tencel™, Liva Reviva™, Refibra™, Sorona®, etc.

Functional Features: Anti-Bacterial and odor-repellent, Anti-static & Hypoallergenic, UV Protection, Water Repellent, Fire Resistance, Sanforizing, Calendaring, Peach, Resin & PU Coating, Enzyme Washed, Soft Touch, etc.

Quality Control : On-site fabric inspections, laboratory testing, and sampling.

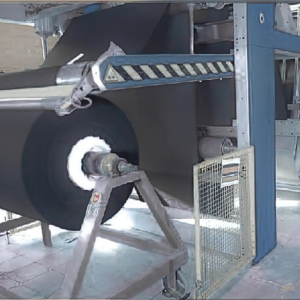

Production Capacity

Weaving Machine | Projectile, Rapier, Air Jet. |

Weaving Capacity | 50,000 – 80,000 Mtr/day |

Dyeing Machine | Rope Dyeing , Sheet Dyeing, & Eco Dye Line. |

Dyeing Capacity | 70,000 Mtr/day |

Finishing Capacity | 65,000 Mtr/day |

Woven Series

As a woven fabric manufacturer, we aim to provide solutions that give clients a competitive edge. We have extensive spinning knowledge and have modernized our mills to use fully automated, ultra-high-speed air jet looms. As a single-source supplier, we offer a range of products from yarn to finished woven fabric, including various weaves and constructions for both tops and bottoms in the export-ready RMG sector.

FABRIC RANGE :

Constructions: Plain, Twill, Satin, Jacquard, Dobby Design, etc.

Fabric Weight: 70–380 GSM

Yarn: Ne 10s to 100s, D-tex 50D to 1200D, Spandex 20D–100D, etc.

Sustainable Options : US Cotton, Recycled Cotton/Polyester, Modal, Tencel™, Liva Reviva™, Refibra™, Sorona®, etc.

Functional Features: Peach, Sanforizing, Calendaring, Moisture-Wicking, Breathable, Anti-Bacterial and odor-repellent, Anti-static & Hypoallergenic, UV Protection, Water Repellent, Fire Resistance, Soft Touch, etc.

Quality Control : On-site fabric inspections, laboratory testing, and sampling.

Production Capacity

Weaving Machine | Toyota, Tsudakoma, Rapier |

Weaving Capacity | 80,000 – 100,000 Mtr/day |

Dyeing Capacity | 80,000 Mtr/day |

Finishing Capacity | 70,000 Mtr/day |

Knit Series

We are committed to leading in producing high-quality knitted fabrics using advanced technology, offering options from coarse to ultra-fine in warp and weft knitting. Our fabric testing lab and R&D team explore future possibilities, focusing on fashion and performance needs in textiles.

FABRIC RANGE :

Fabric Types : Single/Double Jersey, Interlock, Rib, Fleece, etc.

Weight : 90 – 400 GSMYarn : OE, Ne 16s – 60s, D-tex 50D to 1200D, & Spandex 20D–100D, etc.

Sustainable Options : US Cotton, Recycled Cotton/Polyester, Modal, Tencel™, Liva Reviva™, Refibra™,Sorona®, etc.

Functional Features : Mercerized, Anti-Bacterial and odor-repellent, Moisture-Wicking,Peach/Suedding, Brush & Shearing, UV Protection, Breathable, High Durability,Enzyme-Washed, Coated, etc.

Quality Control : On-site fabric inspections, laboratory testing, and sampling.

Production Capacity

nitting Machine | Mayer & Cie, Fukuhara, Jacquard |

Knitting Capacity | 50–60 Tons/day |

Dyeing Capacity | 40 Tons/day |

Finishing Capacity | 30 Tons/day |

We Will Write a Convincing Call To Action to Engage Your Audience Here

We will write a sub-headline that introduces your call to action to website visitors here